Specification for Timber Decking

Timber decks can be designed to meet a variety of service life requirements. Desired service life options of 15, 30 and 60 years are given in European/British standards. For quality installations, 15 years is considered to be the minimum standard. For raised decks and balconies built on new homes, the NHBC requires a 60 year service life in accordance with TDCA Codes of Practice – these documents are available free to download to registered users here.

The principal specification standards to achieve 15 years desired service life are set out below:

Your choice of deck board timber

Choose timber which is either naturally resistant to decay or which has been pressure treated or modified by an industrial process to give long-term protection from decay.

Deck boards

Naturally durable deck boards should be rated as 'moderately durable' (durability class 3) at least for above ground use and 'durable' (durability class 2) for ground contact use.

Pressure treated softwood deck boards should be treated to at least Use Class 3 (outdoor above ground use) with a 15 year desired service life specification. 30 and 60 year specification is also achievable by special arrangement.

Note regarding pressure treated timber

- Whitewood is difficult to pressure treat and should not be used for posts embedded in the ground or for other substructure elements (ie. joists) on the ground or on other non-permeable surfaces (ie. concrete slabs) unless its treatment properties have been improved, for example with incising, to ensure correct preservative penetration in line with BS8417.

- All crosscuts, notches or large boreholes shall be treated on site with a suitable brush applied end grain preservative. Any rip-sawn timber should be returned to the treatment plant for retreatment.

Modified wood deck boards, out of ground contact should be rated as 'moderately durable' (durability class 3) but the durability ratings of modified wood in-ground contact varies, according to the desired life and modification type - always consult the manufacturer.

The timber deck substructure

Treated Timber and Use Classes

For economic reasons the substructure is usually constructed from pressure treated softwood1.

TDCA recommends that deck joists, posts and beams or any  timbers providing exterior structural support should be preservative pressure treated to Use Class 4 - regardless of whether they are in ground contact or not. This is to ensure the enhanced durability and safety of the deck substructure.

timbers providing exterior structural support should be preservative pressure treated to Use Class 4 - regardless of whether they are in ground contact or not. This is to ensure the enhanced durability and safety of the deck substructure.

- The minimum standards for the treatment of wood are set out in British Standard BS 8417 (2014) and the WPA Code of Practice - Industrial Wood Preservation (January 2021). These standards consider all of these elements and gives guidance on the loading and penetration of timber preservative, to ensure treated timber is fit for its desired end use.

Working in tandem with BS EN 335 - Durability of wood and wood-based products, it groups the applications for treated wood into Use Classes. Use Class 4 treatment is for timber in contact with the ground or fresh water, permanently exposed to wetting (and/or providing exterior structural support).

See our blog article here.

Strength Graded Timber

The grade (strength class) of timber used for structural components such as posts, beams and joists shall be sufficient to cope with the loads placed upon it during its service life.

Softwood with a strength class rating of C16 is considered the minimum standard for decks above 600mm in height and is a requirement of building regulations for such raised level structures. For decks below 600mm in height the use of C16 timber is recommended.

The higher strength classes, typically C18 and C24 should be specified where smaller component sections, longer spans or commercial deck performance design considerations are required.

See our blog article here.

Note:

- Do not exceed the recommended load and span for each strength class – refer to span tables in TDCA/TRADA Timber Decking: The Professionals’ Manual for detailed recommendations.

- Use noggins/blocking to strengthen frames where appropriate to prevent flexing.

Posts - appropriate to scale and end use of structure

Posts can be made from laminated sections, solid timber or round poles (see section above on Timber Deck Substructure for Use Classes and Strength Grading). The most commercially available decking posts for domestic projects are 100 x 100mm (nominal size). They should have a load bearing capability/size/spacing appropriate to the scale and end use of the structure.

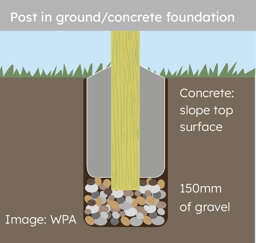

Timber posts can be embedded in a hole in the ground and backfilled with poured concrete (DO NOT make a ‘boot’ for a post out of concrete). Ensure water can drain away from the foot of the post by adding 150mm of gravel to the bottom of the hole for drainage. Always finish the mix level above ground and slope the top surface of the concrete to shed water away from the post.

For extended life surface mounting of posts on pre-cast piers or metal shoes is recommended.

On raised decks it is advised that support posts are not carried through the deck to serve as newel posts for a parapet – these should be considered as a separate component.

Laying a fall in a deck to aid drainage

The requirement for building a slight fall into a decked area is to aid drainage away from any adjacent property. This is usually achieved by adjusting the frame support system (substructure). Creating a fall should not be an issue for a professional installer.

The front beams on which joists sit can be installed slightly lower than the rear beam. Alternatively you can build the beams level and use a suitably durable packing medium to raise the joists at one end. Ground level decks can utilise adjustable deck supports securely fixed to ground and bearer.

Grooved deck boards are designed to assist drainage of surface water, lay them lengthways in the direction of fall. With smooth boards you have the option of laying them either way – with the fall across the width of the boards (because the gap between boards allows drainage) or across the length.

Timber moisture content at installation: 20% maximum

To minimise the effects of shrinkage (eg cupping, cracking, warping), install timber as close as possible to the equilibrium moisture content of the site.

In the UK, outdoor wood moisture content varies from around 19% in winter to 12% in summer. For best results always install wood with a moisture content lower than 20%. The stability of all wood used out of doors can be improved by the use of water repellent timber treatments.

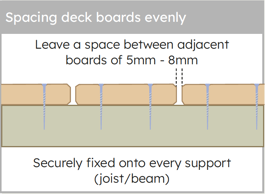

Deck board spacing: 5 - 8mm between adjacent boards

A fundamental aspect of deck installation is to ensure the drainage of water from the surface.

Leaving an adequate space between deck boards helps with this and also accommodates the expansion and contraction of wood as it's moisture content changes with the seasons.

- For adjacent deck boards leave a gap of between 5-8mm. Hardwoods which are classed as 'small movement' can be fitted a little closer than this.

- Board ends can be butted together (but not tightly).

- Leave a 5mm space where a board end abuts a post.

- Where boards abut a building incorporate a 10mm gap

Metal fixings must be suitable for long term, outdoor use

All metal fixings shall be made from corrosion resistant materials such as stainless steel, hot dipped galvanised or other specialist coating.

Before use, verify with the manufacturer that the fixings you have chosen are suitable for use with the timber you have chosen. For example aluminium fasteners should not be used with pressure treated wood. Prevent galvanic corrosion by using the same type of metal for both fixings and connectors.

Deck board fixings

- All fixings should be at least 2.5 times the thickness of the board being fixed.

- Stainless steel annular ring shank nails are economical and less likely than standard nails to pull away although screws provide a number of advantages over nails

- On hardwoods or dense species softwoods, the use of screws is always recommended. Pre-drill pilot holes with 2mm oversized clearance and countersink slightly below the surface.

- At all joist crossing points secure boards with two fixings positioned at the outer quarter points of the deckboard i.e. 25% in from either edge.

- On grooved boards fixings should always be at the bottom of grooves.

- Take care using high-pressure nail guns as they can damage the timber.

Learn more here

Further specification references

TDCA/TRADA Timber Decking: The Professionals’ Manual – third edition 2018

TDCA Technical Bulletin TB02: Statutory requirements

TDCA Technical Bulletin TB04: Parapet design and construction

TDCA Technical Bulletin TB08: Metal fixings

TDCA Code of Practice TDCA/RD0801E6 May 2018 Raised timber deck structures on new homes

Wood Protection Association: Code of Practice - Industrial Wood Preservation

British Standards with relevance to timber decking

The TDCA is an Official Distributor of BSI for BSI standards. You can benefit from a 15% discount on the purchase of any BSI standard acquired through the Association - go to the BSI Standard page

The TDCA is an Official Distributor of BSI for BSI standards. You can benefit from a 15% discount on the purchase of any BSI standard acquired through the Association - go to the BSI Standard page

The Standards set out below all have a relevance to the creation of high performance timber decks.

BS EN 335:2013 Durability of wood and wood-based products. Use classes: definitions, applications to solid wood and wood-based products.

BS EN 350:2016 Durability of wood and wood-based products. Testing and classification of the durability to biological agents of wood and wood-based materials

BS EN 351-1:2023 Durability of wood and wood-based products. Preservative-treated solid wood. Classification of preservative penetration and retention

BS EN 351-2:2023 Durability of wood and wood-based products. Preservative-treated solid wood. Guidance on sampling for the analysis of preservative-treated wood

BS EN 599-1:2009+A1:2013 Durability of wood and wood-based products. Efficacy of preventative wood preservatives as determined by biological tests. Specification according to use class

BS 8417:2011+A1:2014 Preservation of wood. Code of practice

BS 5756:2007+A2:2017 Visual strength grading of hardwood. Specification

BS EN 16737:2016 Structural timber. Visual strength grading of tropical hardwood

BS EN ISO 3506-1:2020 Mechanical properties of corrosion resistant stainless steel fasteners. Bolts, screws and studs with specified grades and property classes

BS EN ISO 3506-2:2020 Mechanical properties of corrosion resistant stainless steel fasteners. Nuts with specified grades and property classes

BS EN 13556:2003 Round and sawn timber. Nomenclature of timbers used in Europe

BS EN 338:2016 Structural timber. Strength classes.

BS 6180:2011 Barriers in and about buildings. Code of Practice

BS EN 1991-1-1:2002 Eurocode 1. Actions on structures. General actions. Densities, self weight, imposed loads for buildings