Timber Preservation

The durability of many commercial softwood timber species can be improved with the application of a wood preservative applied by an industrial process. The process involves a kilning process to dry the timber before it is loaded into a high pressure treatment plant (autoclave) where the preservative is forced into the timber cells under vacuum pressure.

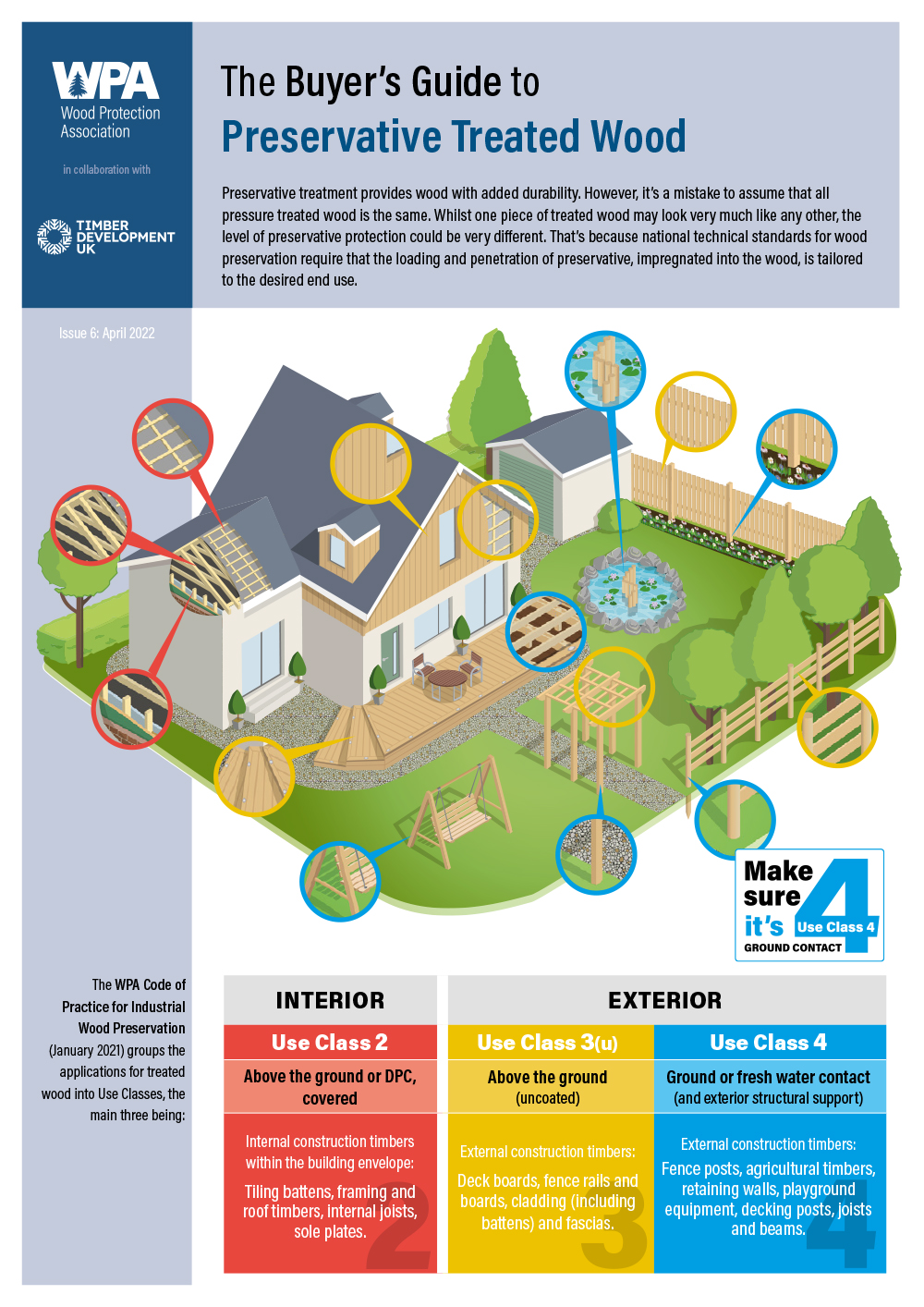

Much of the decking, landscaping and cladding timber products available through trade suppliers have already been treated in this way, but to varying levels of protection.

Treatment parameters vary according to the end use of the timber. It is therefore crucial to know if the treated timber you have purchased is fit for its intended purpose.

The Use Class system

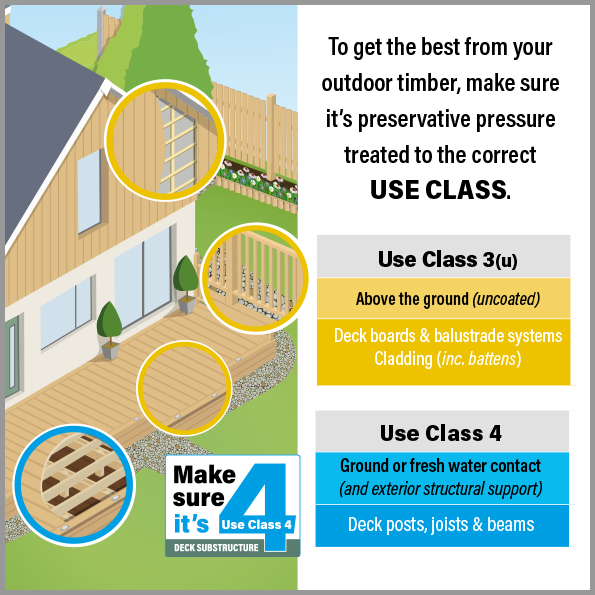

The amount of preservative protection required of timber components is governed by their intended end use situations. These are categorised according to a Use Class system which is detailed in a British/European Standard BS EN 335-1. The relevant exterior grades being:

Use Class 3 - uncoated (u) and coated (c)

For timber products not in contact with the ground and exposed to frequent wetting. Includes: deck components such as balustrades and deck boards; cladding boards and cladding battens.

Use Class 4

For timber products in contact with the ground or fresh water, permanently exposed to wetting*. Includes timber deck components such as posts, beams or joists (and occasionally deck boards that will be in contact with the ground).

*The TDCA recommends that any decking timbers providing exterior structural support should be preservative pressure treated to Use Class 4 - regardless of whether they are in ground contact or not.

This is to ensure the enhanced durability and safety of deck substructures is in line with British Standards – BS 8417 Preservation of Wood: Code of Practice (which is to adopt this change shortly) and the Wood Protection Association's new Code of Practice for Industrial Wood Preservation.

The Wood Protection Association is the UK authority on wood protection. Its website is packed with information about extending the life of wood and protecting it against rot, insects and fire.

Make sure it's 4 campaign

Go to the WPA websiteDownload now

Buyer's Guide To Preservative Treated WoodWe strongly advise you to ask your timber supplier to confirm in writing the Use Class your timber is treated to and the desired service life specification that applies – either 15, 30 or more years, the industry default being 15 years.

Brush-applied wood preservatives or dip treatments are not suitable for the long-term protection of timber used for exterior decking, cladding and landscaping applications and should not be used.

Timber Treatments

The preservative product for outdoor use is generically described as copper organic. An example is Impra®-lit wood preservative. The resulting treated timber has a soft green/brown hue which mellows and matures as the wood ages eventually becoming silver grey in colour. Colour additives can also be incorporated as part of the treatment process. Additional decorative coatings can be applied if desired.

When buying any timber component look for the DeckMark® or CladMark® quality assurance symbol. This is your proof that the product has been independently assessed by the TDCA. Such accredited products and suppliers are widely available across the UK through timber and builders merchants and can be found on this site

Find a treated softwood product

GO TO SUPPLIERSTimber Treatment Service Provider

WJ GroupReferences:

WPA Code of Practice: Industrial Wood Preservation. A valuable and current reference of standards and good practice for treaters, specifiers and users of treated wood. This new publication supports the ongoing education campaign to raise awareness within the wood supply chain for the accurate specification of preservative treated wood products.

This document replaces the former WPA Manual: Industrial Wood Preservation - Specification and Practice.

BS 8417: Preservation of wood. Code of practice: Provides information for the specifier concerning the treatment of timber for use in the UK, drawing upon appropriate portions of the relevant BS EN documents.