What’s lurking beneath your deck?

Friday, February 06, 2026

We recently shared an article highlighting how TDCA services help avoid costly mistakes in decking and cladding projects. In the world of timber decking and cladding, the quality of specification, materials, and installation can vary greatly, and the consequences of getting it wrong can be serious.

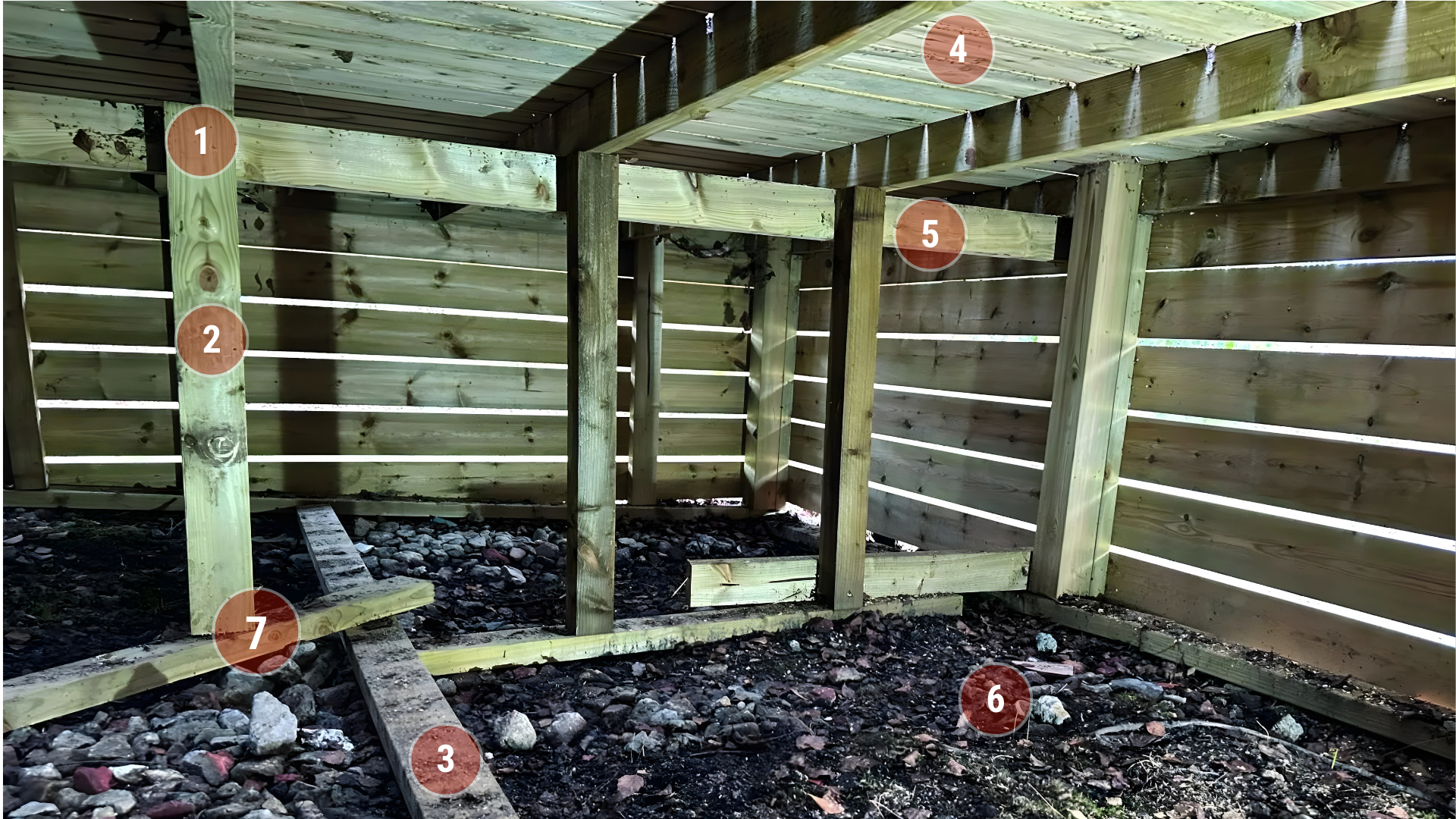

This image was taken during a TDCA inspection visit. From the top, the deck appeared perfectly fine, although localised water pooling had raised the owners' concerns. But underneath, it was a different story. Hidden issues like poor substructure design, inadequate fixings, or incorrect installation can lead to structural failure, safety risks, and expensive remedial work.

We want to highlight the mistakes made here and show how support through TDCA can help avoid these problems in the future….

List of this deck's substructure issues

- 100 x 100mm posts are inappropriate for raised decks.

- Structural support propped up on a joist laid partially on unstable rubble and partially on another section of joist laid on the same unstable surface.

- Documentation confirmed that all timber posts and joists were treated to UC3 which is in appropriate for ground contact using in any case.

- No noggins used between the joists to add rigidity to the joist structure.

- Beam on poorly supported posts. This then supports the joists and deck boards.

- No weed suppressant membrane present.

- Poorly supported post in danger of collapse.

- Poorly supported post in danger of collapse.

Deck substructure assessment

Durability

- The maker’s stamp indicates that the beams and joists used are internal building joists. This means they are treated with a wood preservative for internal use making them wholly unsuitable for external exposure.

- Documentation confirmed that all timber posts and joists were treated to UC3 which is inappropriate for ground contact using in any case. Use Class 4 is required for timber that is in direct contact or in close proximity to the ground and for safety critical structural components.

Structural deficiencies

- Undersized beams and joists: The primary load-bearing members are significantly undersized for their intended span and load, compromising structural integrity.

- Poor post layout: Posts have been arranged in a disorganised and inconsistent manner, with little regard for load paths or stability.

- Inadequate post support: Several posts are precariously balanced on unstable surfaces, while others are effectively suspended in mid-air. Some joists and posts appear to have been laid directly on the ground without any consistent method or rationale- providing only temporary and unreliable support.

- Ground level instability: The absence of proper post foundations will inevitably lead to flexing throughout the substructure. This will manifest as noticeable ‘bounce’ or movement in the deck surface when walked upon and will likely cause uneven settlement or subsidence over time.

Fixing and bracing issues

- Fixing methods throughout the structure are inadequate for the intended use.

- There are no noggins or intermediate bracing between joists to add rigidity and prevent lateral movement.

Additional oversights

- No weed-suppressant membrane or ground preparation has been installed beneath the deck, which will result in vegetation growth which inhibits aeration/ventilation thereby elevating decay risk - good ventilation to underneath is very important.

- No evidence that end-grain preservative has been applied to crosscuts, leaving exposed timber vulnerable to decay.

This is where TDCA support can make all the difference:

- Decking Handbook: Our comprehensive Timber Decking Handbook offers expert guidance on design, materials, fixings, and maintenance — everything you need to get your decking project right first time.

- DeckMark & CladMark Accreditation: Always choose DeckMark-accredited suppliers and installers. These schemes give you confidence that products are manufactured under stringent quality systems and that installers are have the experience and professionalism to deliver work in line with the correct standards.