| Natural Durability Class (BS EN 350:2016) |

Desired service life / years (BS 8417) | |

|---|---|---|

| Occasionally wet1 | Frequently wet | |

| 1 : Very durable | >60 | 60 |

| 2 : Durable | 60 | 30 |

| 3 : Moderately durable | 30 | 152 |

| 4 : Slightly durable | 152 | <152 |

| 5 : Not durable | <152 | <152 |

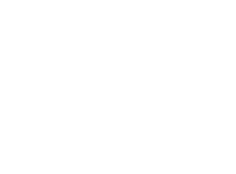

The durability of timber varies between species. Standards assign different species to one of 5 durability classes. The classes apply to the heartwood only, the durability of sapwood is class 5 irrespective of species.

Natural durability classes of heartwood to fungal decay and its relationship to service life:

| Natural Durability Class (BS EN 350:2016) |

Desired service life / years (BS 8417) | |

|---|---|---|

| Occasionally wet1 | Frequently wet | |

| 1 : Very durable | >60 | 60 |

| 2 : Durable | 60 | 30 |

| 3 : Moderately durable | 30 | 152 |

| 4 : Slightly durable | 152 | <152 |

| 5 : Not durable | <152 | <152 |

To achieve a 15 year desired service life specification or more you need to select:

Notes to above table:

Siberian larch is classed as Conflict Wood and is no longer available.

* Where durability class is shown as a range, the lowest durability (highest number) should be assumed unless specific information is available on the source of the wood to be used.

Natural durability classes refer to heartwood only.

BS 8417 gives two treatability classes. These align with BS EN 350 as follows:

Both systems are based on the treatability of the sapwood

Treatability classes (source - BS EN 350):

| Class 1 | Easy to treat |

| Class 2 | Moderately easy to treat |

| Class 3 | Difficult to treat |

| Class 4 | Extremely difficult to treat |

Notes:

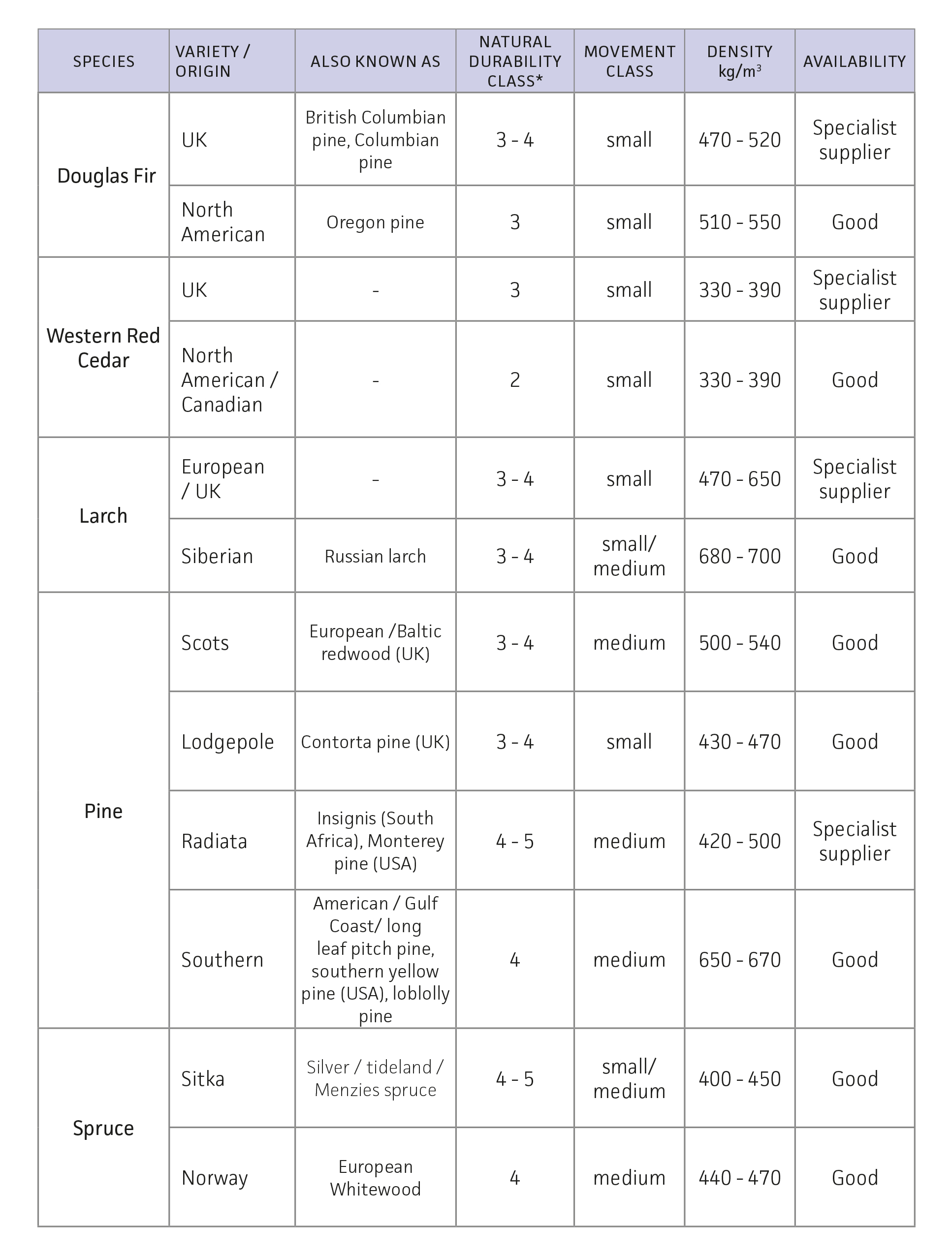

1. Red Grandis is a trade mark for plantation grown Eucalyptus grandis from South America, in this case from Uruguay.

( ) = durability assessed in laboratory tests.

* Where durability class is shown as a range, the lowest durability (highest number) should be assumed unless specific information is available on the source of the wood to be used.

Natural durability classes refer to heartwood only.

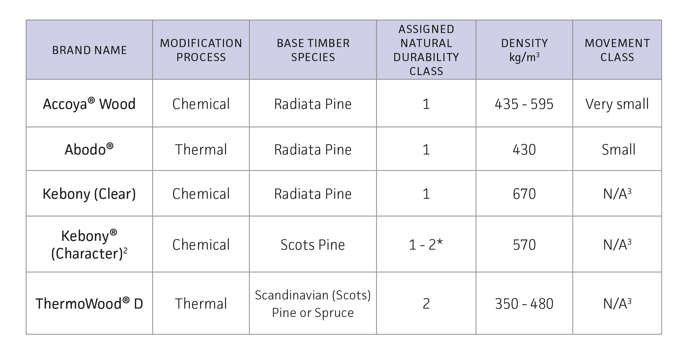

Wood modification is a term used to describe timber that has undergone a chemical, thermal or physical process. The principal aim is to improve durability – resistance to fungal decay - and modified wood processes achieve this without the need to use biocides in contrast to wood preservatives. This essentially creates a new timber product with enhanced performance properties – such as durability and dimensional stability. Modified wood is providing an alternative choice of material for designers and architects to consider – popular for cladding, decking, windows, doors, landscaping and structural applications.

Modified woods are usually more dimensionally stable than unmodified timber. Because modification processes usually change the entire cross section of the timber, products can be machined after the modification process without exposing unprotected areas. Other characteristics like strength and density can be affected but this is not normally an issue cladding applications.

Most modified woods used in cladding are generally rated as Very durable (BSEN350:2 Class 1) or Durable (Class 2) and capable of delivering a desired service life of 30 years or more. Durability against insect attack is also conferred.

It should be noted that much of the performance assessments of modified wood is often based on laboratory tests and so the degree of performance certainty associated with wood preservatives based on field test data and long term use has yet to evolve. The performance properties of modified woods are known to change in relation to the species, the process and variations in process.

The modified wood processes most suitable for cladding are:

Notes:

* Where durability class is shown as a range, the lowest durability (highest number) should be assumed unless specific information is available on the source of the wood to be used

2: Kebony Character contains untreated heartwood – cladding should not be further machined, or split but can be cross cut to length, exposed end grain must be treated with a wood preservative.

3: Information not readily available - refer to manufacturer.

The data in this table is based on laboratory tests and has been verified by the manufacturers of the individual brands. The modification processes change the source species into a higher value commodity and effectively create a new species with enhanced durability and stability characteristics. This is a key factor in improving coating performance compared to the base material.