Cladding Design Considerations

The information below sets out some important aspects that need to be considered at the design stage of a timber cladding project.

Cladding profile styles and board arrangement

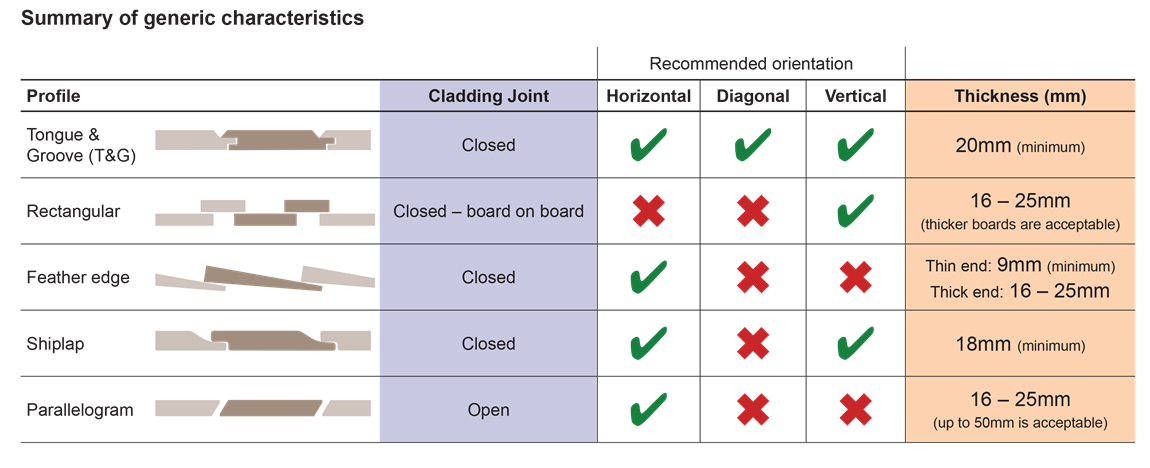

The size, profile and orientation (horizontal, vertical and diagonal) of boards and the natural appearance or addition of colour, offers infinite design flexibility.

There is a wide choice of standard profiles available in softwoods, modified woods and hardwoods. Dimensions and styles can vary from one manufacturer to another so always obtain samples and agree quality parameters prior to confirming your selection.

Refer to British Standard BS 8605, External Timber Cladding Part 1: Method of specifying. for guidance.

Due to the way cladding is shaped, fixed and its natural movement (expansion and contraction) characteristic, some profiles are not suitable for both horizontal or vertical arrangements and only Tongue and Groove (T&G) is recommended for diagonal designs – see the table below.

Open jointed cladding - a chamfered board (parallelogram), horizontally installed is our recommendation for open jointed cladding - read more HERE.

Movement gaps and, for T&G boards, tongue widths and tongue thickness, are dependant upon the width of the board and the movement class of the timber species being used.

Thickness guidance is largely determined by the profile required - as shown above - and width is generally 4 to 6 times board width, with 75 to 150mm being the recommended range apart from for T&G boards, which should be no greater than 125mm wide unless very small movement timber is used e.g. Accoya. Accoya is available in widths up to 195mm.

If you require a bespoke profile or a specific species then contact the TDCA, we will be more than happy to liaise with our members on your behalf.

It is recommended to specify cladding which has recognised, independent quality accreditation such as TDCA CladMark.

Fundamental aspects of Cladding Installation

- The external cladding assembly is in the wet zone of the external wall.

- The cladding acts as a rainscreen deflecting wind driven rain away from the building.

- Cladding is fitted over a drained and ventilated cavity, ventilated top and bottom, created using a series of battens. Cladding in vertical arrangement requires a counter batten layer to create the cavity.

- A breather layer separates dry and wet zones and is fitted behind the batten layer.

- Read this blog about drainage and ventilation

Timber Selection and Durability

Timber cladding relies on good design and material specification to provide reliable performance.

In a temperate climate like the UK, durability (the ability to resist wood destroying organisms) is the critical consideration when choosing timber cladding. Durability can be either a natural characteristic of a particular species or it can be conferred on a species by preservative pre-treatment or a wood modification process.

Timber used outdoors and above ground (such as cladding) is termed as Use Class 3 in standards (BS EN 335 Part 1) and this class is split into coated and uncoated applications.

The risk of insect attack is often considered small in the UK save for those localised areas where the house longhorn beetle, death watch beetle and termites exist. Powder post beetle is a threat to Oak sapwood but this can be eliminated by specifying that all sapwood be excluded. If this is not viable, then like all other species, oak can be made resistant to insect attack by pre-treatment with a preservative.

Climate Change factors are assuming an increasing importance in the development of British Standards. According to Defra, those involved in designing buildings with a life in excess of 60 years must take into account the consequences of a warmer, wetter and occasionally more extreme climate than in the past. Increasing warmth and wetness are the conditions that encourage decay and insect attack. As a consequence, specifying timber cladding with more than sufficient ability to deal with climate change is recommended.

Timber Selection and Service Factors

The ease of being able to access cladding for maintenance, repair or replacement is also a key element in timber choice.

If access is relatively easy and regular maintenance costs are acceptable then you can consider a wider range of options – including lower durability species. Where access and so maintenance, is less easy or expensive or the consequences of failure are not acceptable then species with medium to high durability should always be selected.

The table below sets out the service factors that help to determine what level of durability is required. Service factor C is typical for cladding.

| Service Factor Code | Description of risk and consequences of failure |

| A | Negligible risk of failure. Enhanced durability optional. |

| B | Where risk of failure is low and use of materials with enhanced durability can be regarded as an insurance against cost of repairs, and/or where replacement of timber or remedial action is not difficult or expensive. |

| C | Where risk of failure is high and/or where replacement of timber or remedial action is difficult and expensive. Enhanced durability is desirable. |

| D | Where risk of failure is very high and/or where failure of timber components would result in serious danger to structure or persons. Enhanced durability is essential. |

Service Life

The benchmark for service life of wood in construction is set out in BS 8417: Timber Preservation - Code of Practice. This standard defines three service life categories: 15, 30 and 60 years. The desired service life required for timber cladding should always be included in the specification.

The industry default specification for pressure treated cladding is 30 years.

When relying on naturally durable heartwood, the desired service life will depend on the durability class of the species selected.

Desired service life categories are not guarantees of performance but indications of the expectation against which the durability performance benchmarks are set. They assume good design detailing, installation practice and normal conditions of use. Other factors, such as degree of exposure of the building to the elements, mechanical damage, vandalism or failure of other elements, may limit the service life of any construction.

Moisture and Movement

Wood is hygroscopic, meaning its moisture content is affected by changes in temperature and relative humidity of the surrounding environment. This results in movement across the grain of the timber.

In some instances, shrinkage may result in cladding boards pulling apart or exposing uncoated timber on cladding that has been painted or stained after installation. Expansion coupled with inadequate movement gaps during installation can result in boards bowing or pulling away from their fixings.

Different species have different degrees of movement and are assigned to movement classes - see cladding wood types.

Movement must be accounted for when specifying, designing and installing cladding.

The moisture content of external cladding can fluctuate from around 10% in summer and 22% in winter or after heavy rain.

Design measures to minimise effects of moisture and water

- At the time of installation timber cladding should have a moisture content of around 16%*.

- Use species regarded as being dimensionally stable or with small to medium movement characteristics for cladding.

- Only wood that has been specifically processed for external timber cladding should be specified.

- Design detailing should include measures that minimise water penetration.

- Tongue and groove boards should have a tongue of sufficient length to prevent disengagement when movement or shrinkage occurs.

Designers, manufacturers and specifiers of timber cladding should adhere to the guidelines set out in BS 8605-1:2014 External timber cladding - method of specifying. - Well maintained surface coatings help to deflect water and reduce movement. If cladding is to be finished with a pigmented coating, application of the basecoat and at least one top coat is recommended before installation.

- Design features such as eaves and overhangs help to deflect rain. Where this is not feasible flashing should be used to protect the tops of cladding boards.

- Prevent splash lines by finishing cladding at least 200mm from the ground or a horizontal surface and where possible use a surface that diffuses falling rain and run off e.g. gravel.

*The only exception to this is where unseasoned wood is the desired cladding material e.g. 'green oak' for which additional allowances are made for movement in its design and fixing as shrinkage will occur as the material dries out.

Take a look at our FAQ's section - Board end joists: butt together or leave a gap?

Decay and Surface Moulds

The risk of decay and surface moulds is significantly reduced if the moisture content of the timber cladding remains below 20% during service. Design and installation should include:

- measures to prevent the uptake of additional moisture through the end grain and

- configurations that discourage water retention.

The threat of fungal decay is eliminated by the specification of timber cladding with appropriate durability for the desired service life required.

Fungi becomes inactive below 5°C. The impact of climate change and warmer winters must be taken into account in specifying durability.

Location and Aspect

The location and aspect of the cladding will have bearing on the design, timber selection and the need for a coating or finish:

- South or west facing aspects are more exposed to both sunlight and driving rain so will weather more quickly.

- Northerly or eastern facing walls will be shaded and appear darker and may require more frequent maintenance.

- Shade from a canopy, overhanging trees or nearby buildings may also have a localised impact and cause variations in colour on the same elevation.

To counteract these factors or simply to add another dimension to your cladding, various types of coatings and finishes are available. Many have water repellent and/or UV protection built-in. There are translucent paints and stains offering partial colour effects and solid pigmented coatings which give a completely opaque look. Most clear oils are of limited use - refer to product supplier for guidance.

Impact on adjacent surfaces

-

Leaching of extractives from some species can cause water marking and stain adjacent materials.

- Leachate is acidic and will cause corrosion and surface staining when in contact with metals

Care should be taken to avoid the staining of adjacent surfaces by the water soluble tannins in some species like Oak and Ipe.

Timber is an organic material. As such it contains a wide range of natural chemicals. Because of their ability move as a liquid these chemicals are collectively referred to as “extractives”. Extractives tend to be more prevalent in the heartwood of a species where their concentration can be a principal cause of the darker colour of the heartwood of a naturally durable species like oak and western red cedar. Water soluble extractives such as Tannin can be leached from cladding by rain. This can leave affected surfaces with an uneven watermark until the surface has been fully leached.

Extractives like tannin in Cedar or Oak or lapachol in Ipe can stain adjacent surfaces like flashings, rendered walls and masonry which can be unsightly. Affected surfaces can be cleaned with dilute bleach, household detergent or a pressure spray. Testing a small area first is recommended.

Tannins in wood are acidic and as such leachate and the wood itself may react with certain metals that they come into contact with and cause corrosion. Contact with iron for example manifests itself in black discolouration. This typically occurs when the wrong type of fixing is used and the surface of the cladding is covered with black spots and stains from each fixing point.

Fire Protection

Where building regulations require fire performance in accordance with British Standards, typically Euroclass B or C (Class 0 or Class 1), the TDCA recommends pre-treatment with a quality assured flame retardant (FR) product applied by a processor approved by the product manufacturer.

Designers should satisfy themselves that the description of the performance achieved in fire test 'classification reports' corresponds with the species and size of cladding that they plan to specify.

The principal source of guidance on industrial flame retardants is the Wood Protection Association (WPA) who also administer the WPA Benchmark Quality Approval Schemes – providing valid independent assessment and verification for timber treatments.

See FAQ: 'Should timber cladding be flame retardant treated?'