Cladding Finishes

Many cladding timbers can be left uncoated to weather naturally - changing in appearance with exposure to the elements, depending on the aspect of the cladding.

The orientation of the cladding on the building will have a material impact on the rate of weathering.

-

South or west facing are more exposed to both sunlight and driving rain so will weather more quickly. Northerly or eastern facing walls will be shaded and appear darker and may and may require more frequent maintenance.

-

Shade from a canopy, overhanging trees or nearby buildings may also have a localised impact and cause variations in colour on the same elevation.

Many coating products are available if you wish to counteract these factors, or simply add another dimension to your project. Adding a coating may be a recommendation of the supplier/manufacturer for a particular species or type.

-

In order to deliver the desired service life, any coating applied must be maintained in good condition in accordance with the manufacturer’s guidance.

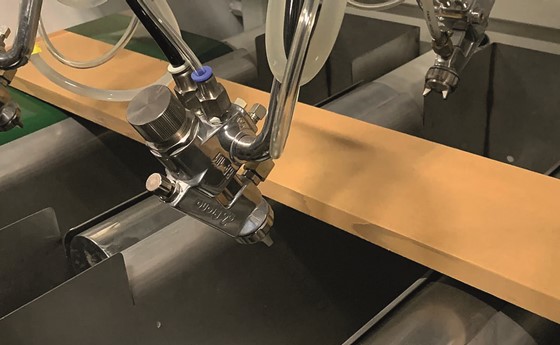

Factory applied coatings and factory finished cladding

Products can be applied by brush or spray on site but it is the full factory finishing of cladding with an extended maintenance system that is best for long term performance.

- With site applied coatings, TDCA recommends that at least one coat is applied to all faces including the end grain, prior to installation. Further coats can then be applied to the visible face.

- Several members offer factory finished cladding products featuring colour and/or textural elements

Factory Finished Cladding

FIND A SUPPLIERCoating Service Providers

FIND A SUPPLIERProduct suitability

Various products are suitable for cladding ranging from clear water repellents to translucent stains and solid pigmented paints. Surface coatings work best on timbers that are dimensionally stable or have a low potential for moisture change movement. The process of preservative treating or modifying wood has a positive impact on coatings adhesion. Surface texture is also important and coatings generally perform better applied to sawn rather than smooth planed timber.

-

The use of moisture permeable coatings is highly recommended. These coatings have been specially developed for external timber as they are resistant to cracking, flaking and peeling associated with more brittle varnishes or paints which can trap water under their surface.

-

Highly pigmented coatings resist weathering best. Paler colours, especially white, also reflect the heat.

See our Coatings manufacturers below.